Capacity Planning in Manufacturing Industry

Access production planning software ensures that you are utilising every machine employee and resource to its full capacity. The first is the maximum work that is completed in a specific period by an organization and the latter is the.

Production Capacity Planning Tools

This is the only way to anticipate how much of each resource you will need in order to create X amount of products.

. Make to Stock MTS Make to Stock is common within discreet manufacturing and process manufacturing. You may also pinpoint potential risks and. Designated Manufacturing Inspection Representatives DMIRA DMIR is an individual appointed in accordance with 14 CFR 18331A DMIR conducts conformity inspections during the manufacturing processDMIRs also issue certificates such as airworthiness certificates for aircraft export certificates for aircraft and parts and special.

The recovery gained momentum in 2021 on the heels of vaccine rollout and rising demand. Industry 40 IIoT and digitisation are currently some of the most-discussed and yet least understood topics within manufacturing today. For example say that a plant has 50 machines and workers can use the machines from 6 am.

Capacity planning means knowing the maximum capacity your operation can managethe absolute most of a product or service it can offer during a period of time. In most manufacturing environments capacity planning is often done at different levels. But this is the trajectory for US manufacturing in 2022 emerging from the pandemic.

Manufacturing Production Planning and Scheduling Software. Download original report pdf At the end of World War II an era of unprecedented industrial expansion opened in. With traditional MRP the material plan must be validated against capacity using a separate capacity planning tool.

Examples of capacity constraints include production resources like ovens or painting lines tooling or specially trained technicians. The Automotive News mission is to be the primary source of industry news data and understanding for the industrys decision-makers interested in North America. The purpose of this information is to detail the arrangements for delivering industry placements through the CDF for those providers in receipt of a CDF allocation in 2020 to 2021.

Determining capacity requirements analyzing current capacity and planning for the future. Industry-specific features like job costing and work-in-progress reports are also included. While this is a workable solution that.

2022 manufacturing industry outlook Manufacturers eyeing growth It is unusual to see positive economic indicators paired with historic labor and supply chain challenges. When you dont know the production capacity your production planning is like taking. Manufacturing planning and scheduling software helps production managers by using mathematical models to better simulate and understand the production environment.

With still a lot of confusion surrounding Industry 40 today well be exploring the key technologies behind Industry 40 as well as real-world applications. So the supply chain managers focus on effective capacity planning in the production process of supply chain management. To gain a better grasp on how each applies to the planning process let us take a closer look at each one individually.

Capacity planning is defined as a method to gauge the production capacity needed to meet the changing product demands of an organization. Industry 40which includes connectivity advanced analytics automation and advanced-manufacturing technologies Exhibit 1was gaining momentum before COVID-19 helping companies transform their operations in everything from production efficiency to product customization with improvements in speed to market service effectiveness and new-business. The first step in understanding production capacity is to calculate the machine-hour capacity of the factory or manufacturing plant.

For planning purposes manufacturers want to know how many hours in a said week or month would each of these resource. Two terms of design capacity and effective capacity are used extensively in the context of capacity planning. Medium or aggregate planning uses a 12-18-month planning window to provide a longer view that allows the organization to ensure that demand can be.

The first step of capacity planning is to. AMERICAN SOCIETY OF PLANNING OFFICIALS. The Surat-based solar module manufacturer Navitas Solar has clocked over Rs 162-crore revenue in FY22 and recently announced its plan to reach Rs 250-crore revenue in FY23The firms Director and Co-founder Ankit Singhania tells ETEnergyWorld that it is focusing on new technology while.

Contact Us 1155 Gratiot Avenue. The company aims to reach Rs 2000 crore by 2025. The daily plant capacity in hours is 16 hours multiplied by 50 machines or 800.

As these operations often have complex multi-level BOMs. Machines people and tools. Planning can be executed in finite or infinite capacity mode and planning time periods can be days weeks months or a combination of all three.

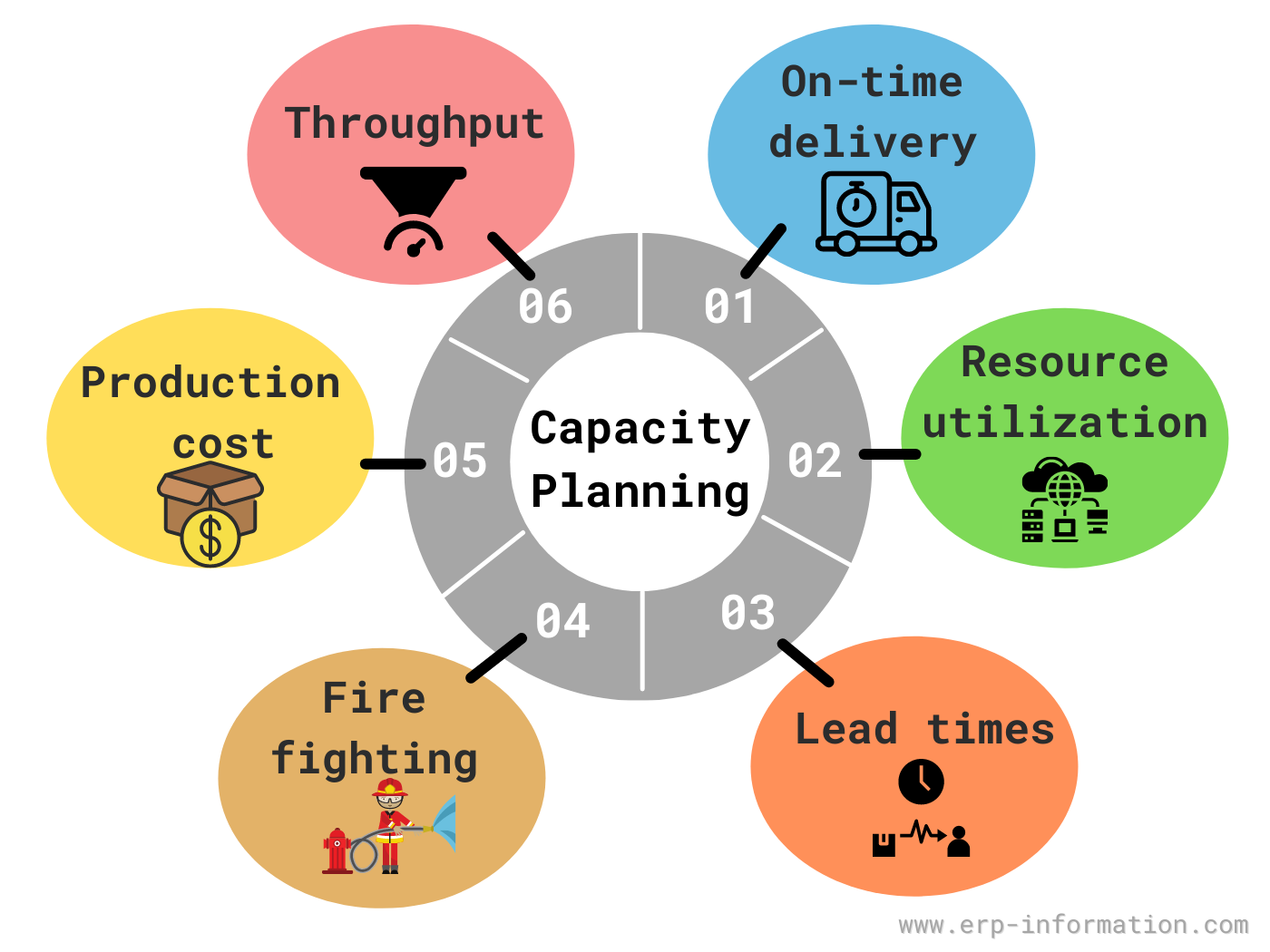

Having a plan in place will ensure that you have the. Practical examples of models in capacity planning for different production modes include. With regard to the manufacturing industry the process of Capacity Planning is made up of three resource types.

Industry 40 in a nutshell. More advanced than standard MRP. From the 2021 to 2022 academic year onwards we are keen to ensure that CDF delivery facilitates sufficient capacity building for industry placements across relevant programme areas as we roll out.

This two-step iterative process can be time consuming. Planning for capacity breaks down into three steps. One or more of these types of resources are used to perform an operation on a job.

Capacity planning and techniques will function differently depending on production mode. We hope you enjoy this fascinating snapshot of a planning issue of yesteryear. This is where you get an overview of your entire business from how much work you can do to how much you can take on at any given point.

The purpose of production capacity planning tools is to assist the sales team to ensure the companys ability to fulfill customer demand. A rough cut planning is usually done at the master schedule level and this is used for short-term planning may be for a week to two months. Limited capacity planning scheduling and optimization.

1313 EAST 60TH STREET CHICAGO 37 ILLINOIS. Industry-specific features such as repairable parts maintenance RPM and more. The 3 types of capacity planning.

There are three main types of capacity planning that you need to be aware of before you get started. Improve the quality of your products by sending quality-related information across your business. Production plans can be changed quickly and easily and are visible to the right people at the right time.

Capacity planning for production is relevant to the product demandsupply concept. You can analyse capacity and test different scenarios to answer what if questions and identify issues before they occur. Simulations including transactional simulation.

Advanced Scheduling functionality considers the availability of resources and additional constraints such as tooling and materials to ensure an accurate model of the manufacturing environment. Tweet on Twitter. Until 10 pm or for 16 hours a day.

What Is Capacity Planning Strategies Tools And Process

Capacity Planning Template Best Of Our Team Demandcaster Excel Templates Simple Business Plan Template Capacity Planning

Best Manufacturing Planning Software For Manufacturing In 2021 How To Plan Planning Maps Capacity Planning

Production Capacity Calculation Template Capacity Planning Capacity Historical Data

Comments

Post a Comment